Submersible Ultrasonics Cleaners With 3000W Ultrasonic Power For

Passivation Tank

1. Common Applications – Advantages of Immersible Ultrasonic

Cleaning Transducers

Drop in ultrasonics to existing manufacturing cleaning process

lines, such as aqueous cleaning lines, passivation, plating lines,

or other part finishing processes which require microscopic surface

scrubbing agitation.

The heavy-duty design of the stainless-steel box has completely

sealed components, which allows for precision ultrasonic cleaning

in conditions normally too harsh for such precision electronics.

Valve bodies and manifolds with small internals not accessible for

cleaning by forced spray or mechanical removal.

Medical device stainless steel parts cleaning.

Aerospace parts cleaning.

Ultrasonic part cleaning of water soluble machining coolants,

chips, particulate, and true machining/cutting oils, buffing,

polishing and lapping compounds which require mechanical surface

scrubbing to remove.

General washing for maintenance, manufacturing, rework and/or

remanufacturing.

2. Common Configurations

Since submersible ultrasonic boxes are most commonly added to

existing stainless steel and other metallic based tanks, the boxes

and ultrasonic power are made to fit such tanks. We can easily make

our immersible ultrasonic cleaning transducers into any tank

configuration sizing required for your application with little to

no additional custom size pricing.

Any tank can become an ultrasonic cleaning tank with Kaijo’s

drop-in Immersible Ultrasonic Transducer. Made from highly polished

316L stainless-steel, these transducers may be used with any model

Kaijo generator. The transducer assembly is hermetically seal

welded with a stainless steel back cover. This ensures the

water-tight submersible ultrasonic transducer that will reliably

operate in any cleaning tank.

3. How Ultrasonic Cleaner Work?

Ultrasonic cleaner is working through a vibration over 20KHz (usually from 20–400KHz). When the vibration transfers to cleaning liquid, it will generate

millions of bubble and these bubbles will break in very short time.

It will generate huge pressure in this process. We call it

cavitation. The pressure will take away the contaminant on cleaning

parts.

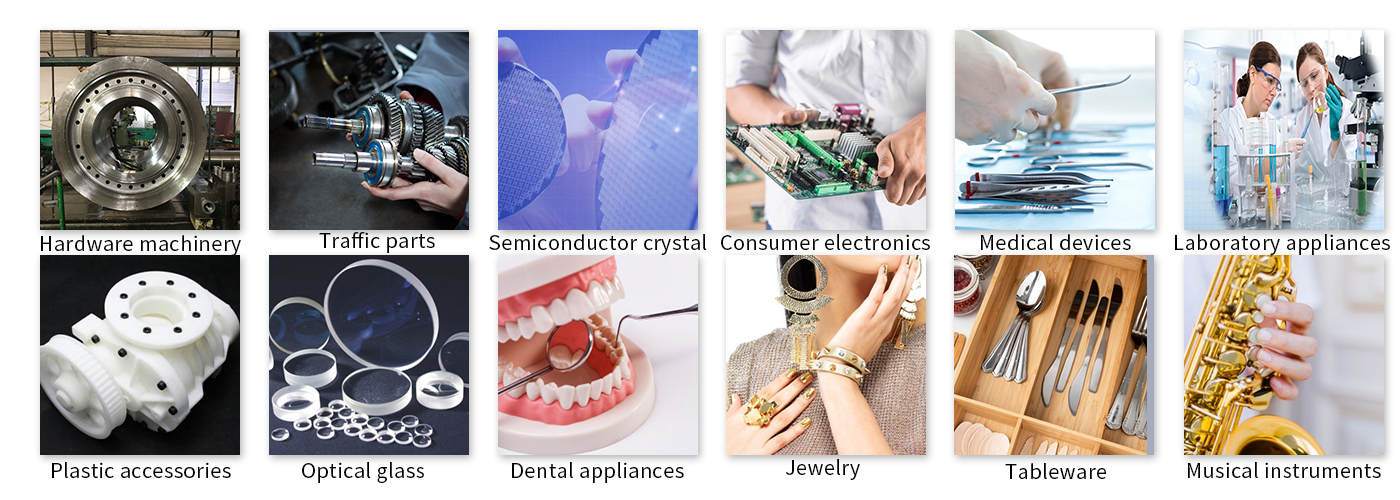

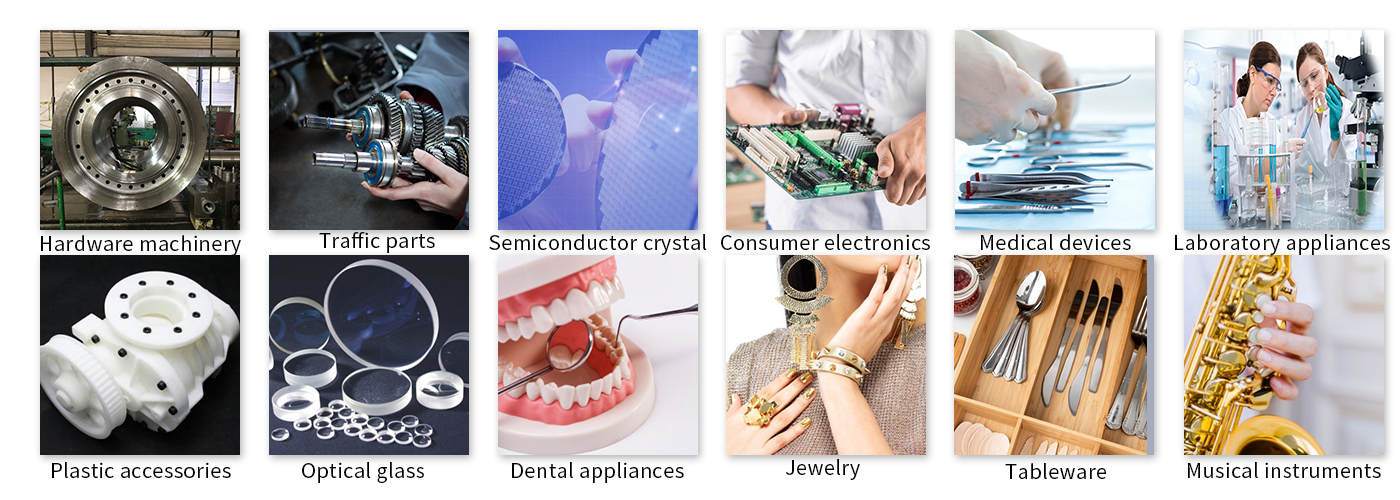

Ultrasonic cleaners are used to clean many different types of

objects, including jewelry, lenses and other optical parts,

watches, dental and surgical instruments, tools coins, fountain

pens, golf clubs, fishing reels, window blinds, firearms, car fuel

injector, musical instruments, gramophone records, industrial parts

and electronic equipment. They are used in many jewelry workshops,

watchmakers' establishments, and electronic repair workshops.

4. The Comparison Of Ultrasonic Cleaning And Traditional Cleaning:

| Comparing Item | Traditional Cleaning | Ultrasonic Cleaning |

| Cleaning Time | Slower | Faster |

| Safety Level | Low | High |

| Labor Cost | High | Nearly Zero Labor Cost |

| Harmful Level | Sometimes It Will Be Harmful | Nearly Zero Harm |

5. Application:

| Industry | Cleaning Objects |

| Auto industry | engine parts, gear box, shock absorber, auto nozzle, cylinder,

valve, Carburetors |

| Electrnoincs | PCB board, electronic parts, TV parts, computer parts |

| Aerospace and marine parts | Turbine blades, Marine Engine components, Overhaul parts,

Pneumatics |

| Machinery | Moulds, precision parts, pressing parts, camera parts, bearing,

hardware tools |

| Plating and Painting | polishing parts, SUS cutter, tableware, plating |

| Food industry | Oven tray, boiler, bottles, bottle cap, Hood Filters |

| Optical& watch tool | optical lens, eyeglass, sunglass, metal, gold, jewelry, diamond,

watch band, watch cover, watch hand |

| Jewelry | Jewelry, diamond, gold, silver products |

| Dental and Medical | Dental Device, Medical Implant, beakers, bottles, vials, pipettes,

or other labware.

|

6. Cleaning Effect: